Products

CIRCOR is a world leader in the manufacture of positive displacement pumps and related technology for use in the industrial, oil and gas, and power-generation industries. By providing reliable fluid handling solutions for numerous applications, Circor has built strong and lasting partnerships with global firms and regional operators. Circor’s product line includes industrial pumps, injection pumps, transfer pumps, specialty centrifugal pumps, and rotary screw pumps (two-screw, three-screw, and progressive-cavity).

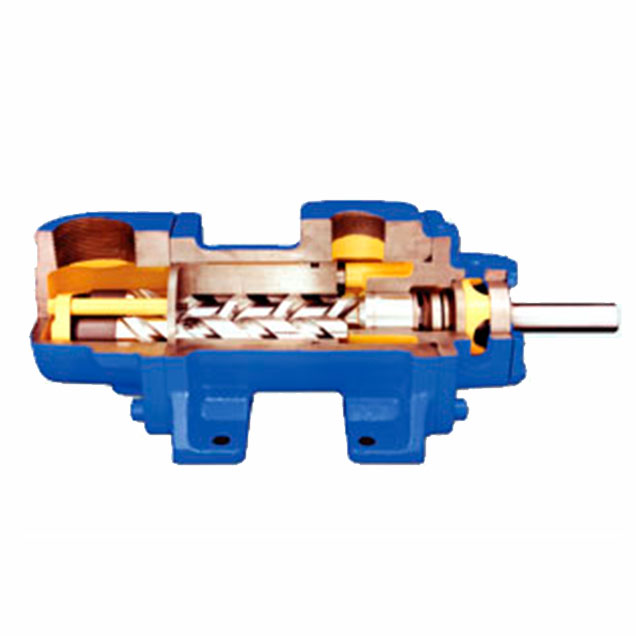

3-Screw Pumps, single or double suction and screws fabricated in several metal options. Made in the USA.

Centrifugal Pumps for corrosive, high temperature and special fluids. In-line design, Block design, horizontal and vertical configurations.

Made in USA.

High Precision Dousing Pumps certified for food, pharmaceutical and chemical industries. Fabricated in several materials and metal combinations.

Made in USA.

Centrifugal Pumps for corrosive, high temperature and special fluids. In-line design, Block design, horizontal and vertical configurations.

Progressing Cavity Pumps ideal for fluids that are corrosive, abrasive, with suspended solids, flammable and explosive. Fabricated under API standard with rotor in several metals and stators in Neoprene, Buna, Rubber and Viton suitable for any application. Made in Germany.

Progressive cavity pump with a rotor and stator suitable for all types of fluids. The stator is made from Buna, neoprene, rubber, and Viton.

High Precision Dousing Pumps certified for food, pharmaceutical and chemical industries. Fabricated in several materials and metal combinations.

Made in Germany

High Precision Dousing Pumps certified for food, pharmaceutical and chemical industries. Fabricated in several materials and metal combinations. Made in the USA.

3-Screw Pumps, single or double suction and screws fabricated in several metal options. Made in the USA.

Centrifugal Pumps for corrosive, high temperature and special fluids. In-line design, Block design, horizontal and vertical configurations.

Made in India.

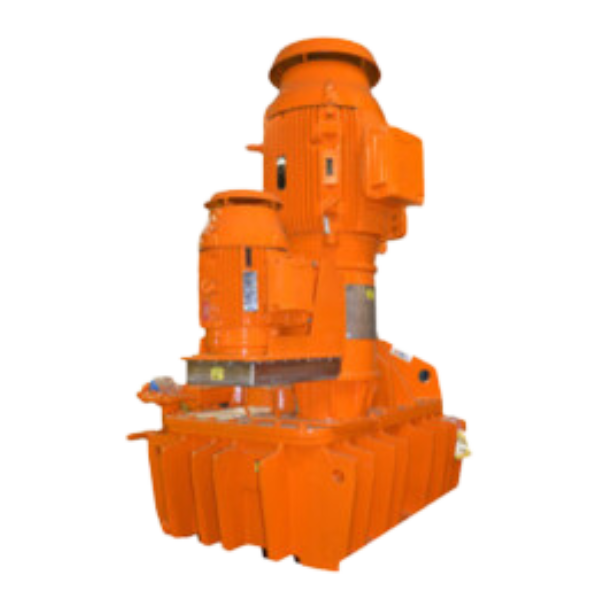

SPX FLOW is a global leader in the research and development of energy-saving industrial solutions and custom process design. SPX FLOW application engineers develop customized mixing and blending solutions to the specific process needs of a customer. SPX Flow custom process solutions are optimal industrial mixing technologies constructed to fulfill process needs and reduce operating cost through a mix of efficient design and aftermarket services.

Manufacturing and material processes developed under standards that meet any requirements for food, pharma, industrial, and oil & gas industries.

Versatile machine design, which allows for maintenance of internal parts, without the need to clear out the mixing tanks.

Variety of impellers: radial, axial, combined, and/or for specialty uses.

Custom-made configurations and mixer functioning, based on client’s needs.

Side entry mixers.

Versatile machine design, which allows for maintenance of internal parts, without the need to clear out the mixing tanks.

Variety of impellers: radial, axial, combined, and/or for specialty uses.

Custom-made configurations and mixer functioning, based on client’s needs.

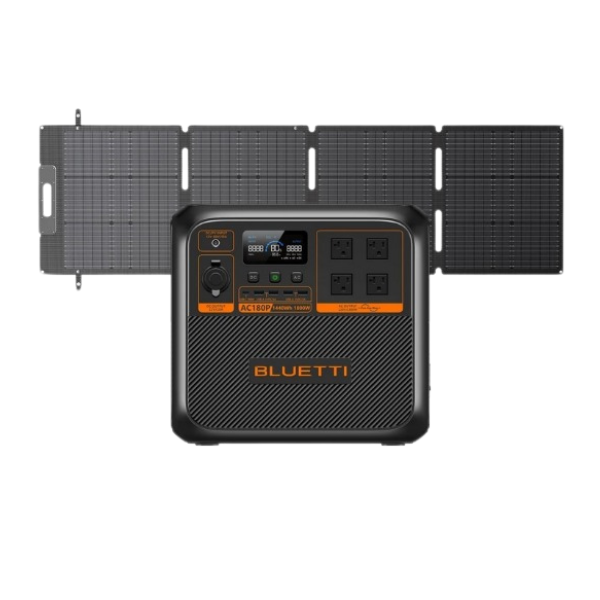

BLUETTI is a leading company in clean energy solutions with over 10 years of experience, offering a broad and reliable portfolio of products ideal for outdoor adventures, emergency backup, and off-grid living. Committed to sustainability, BLUETTI operates in more than 110 countries and is trusted by millions of customers worldwide.

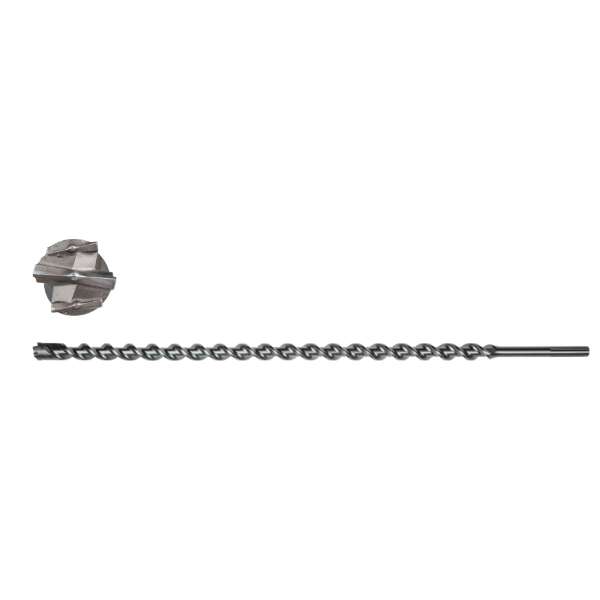

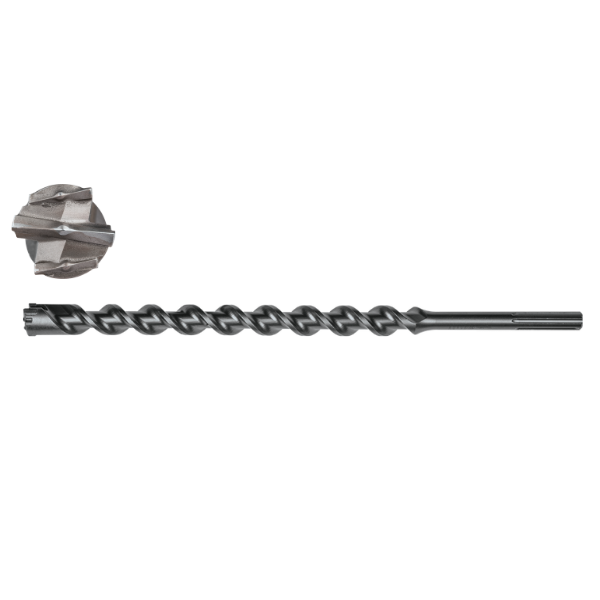

Makita Corporation, founded in 1915 in Nagoya, Japan, began as a company specializing in the sale and repair of electric motors. With over a century of innovation, Makita has established itself as a global brand present in more than 40 countries, offering a wide range of high-quality power tools and cordless products. Its commitment to research and development has allowed the company to stay at the forefront of technology and meet the needs of professionals across various industries.

HR006GZ

2-1/16” 80V MAX (40Vx2) SDS MAX AVT SDS MAX Rotary Hammer (21.4 J / 15.7 Ft. Lbs Torque)

OILSUPER S.A. is the company responsible for distributing Total brand lubricants in Ecuador, offering a comprehensive portfolio of products for the automotive, industrial, marine, and other sectors. Total Lubricants, founded in 1924 as Compagnie Française de Raffinage (CFP), is one of the five largest oil companies in the world, with a presence in over 130 countries and more than 100,000 employees. The company operates across all areas of energy conversion, including wind, solar, and oil production. In the field of lubricants, Total provides specialized products for various industries, light and heavy vehicles, motorcycles, agricultural equipment, aviation, and all types of vessels.